What is Multi-Warehouse Management?

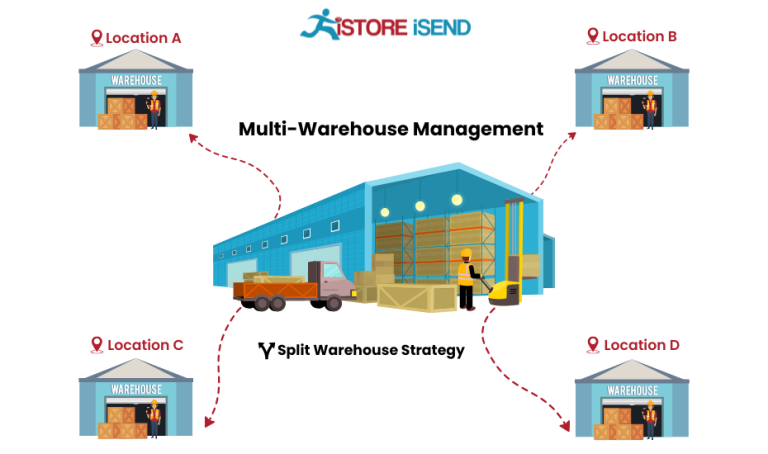

Multi-warehouse management involves coordinating and overseeing the operations of multiple storage facilities within a supply chain. This approach allows businesses to strategically position inventory across different locations, improving delivery times and reducing transportation costs. Companies like iStore iSend utilize multi-warehouse management to enhance their logistics services, ensuring that products are stored and delivered efficiently to meet customer demands.

The Importance of Multi-Warehouse Management

Meeting Customer Expectations

As businesses expand, so does the need to meet customer expectations for faster delivery times and improved service levels. Multi-warehouse management allows companies to position inventory closer to their customers, reducing shipping times and costs. For businesses like iStore iSend, which provide fulfillment services not only to e-commerce but also to retail and a variety of business types including B2B2C and offline to online models, the ability to manage multiple warehouses efficiently is a key competitive advantage. It enables them to offer quicker turnaround times, which is critical in an era where next-day or even same-day delivery has become the norm.

Enhancing Inventory Accuracy and Availability

Multi-warehouse management ensures that inventory is not only accurately tracked but also optimally distributed across different locations. This reduces the risk of stockouts and overstocking, which can lead to lost sales or excess holding costs. By leveraging advanced inventory management systems, businesses can maintain real-time visibility of their stock levels across all warehouses, ensuring that products are always available when and where they are needed.

Challenges in Multi-Warehouse Management

Complexity of Coordination

One of the most significant challenges in multi-warehouse management is the complexity of coordinating operations across different locations. Each warehouse may have its own set of processes, staff, and systems, making it difficult to ensure consistency and efficiency. This complexity can lead to communication breakdowns, inventory discrepancies, and delays in order fulfillment. Addressing these challenges is crucial for maintaining high levels of customer service and operational efficiency in any business.

Inventory Discrepancies

Managing inventory across multiple locations increases the risk of discrepancies. Without a centralized system, it becomes challenging to track inventory movements accurately, leading to errors in stock levels and fulfillment. This can result in delayed shipments, incorrect orders, and dissatisfied customers. That’s why partnering with a reliable 3PL provider, especially one that utilizes a smart warehouse management system like ODIN, is so important. Implementing a robust WMS that integrates all warehouse operations is crucial for minimizing these risks.

Logistics and Transportation Costs

Operating multiple warehouses can also lead to increased logistics and transportation costs. Without proper planning, businesses may face inefficiencies such as redundant shipments, higher fuel costs, and increased labor expenses. For a reliable 3PL and fulfillment center can actually help in optimizing transportation routes, consolidating shipments, and strategically locating warehouses are essential strategies for controlling costs and maximizing profitability.

Technological Solutions for Multi-Warehouse Management

A robust Warehouse Management System (WMS) is at the heart of effective multi-warehouse management. A WMS allows businesses to automate and streamline many aspects of warehouse operations, from inventory tracking and order fulfillment to labor management and reporting. For iStore iSend, implementing their own WMS which is ODIN to efficiently manage inventory across multiple locations, ensuring accuracy and consistency in order processing.

Real-Time Data and Analytics

The integration of real-time data and analytics is another critical component of multi-warehouse management. By leveraging technologies such as the Internet of Things (IoT) and artificial intelligence (AI), businesses can gain insights into warehouse operations, predict demand, and optimize inventory levels. Real-time tracking also allows for better decision-making, enabling companies to respond quickly to changes in demand or disruptions in the supply chain.

Cloud-Based Solutions

Cloud-based warehouse management solutions offer the flexibility and scalability needed to manage multiple warehouses. These systems provide real-time access to inventory data from anywhere, allowing businesses to monitor and manage their operations remotely. For iStore iSend, cloud-based solutions enable them to scale their operations as their client base grows, adding new warehouses without significant disruptions to their existing processes.

Best Practices for Inventory Optimization Across Multiple Warehouses

Demand Forecasting

Accurate demand forecasting is essential for balancing inventory levels across multiple warehouses. By analyzing historical sales data, market trends, and seasonal fluctuations, businesses can predict demand and allocate inventory accordingly. This ensures that products are available in the right quantities at the right locations, reducing the risk of stockouts and overstocking.

Automated Replenishment Systems

Automated replenishment systems help maintain optimal inventory levels by triggering restocking orders when inventory falls below a certain threshold. This reduces the likelihood of stockouts and ensures that each warehouse has sufficient stock to meet customer demand. Most 3PL fulfillment centers offer this feature in their systems or send out alerts,as automation is key to managing inventory efficiently across multiple locations, especially during peak seasons.

Safety Stock Management

Safety stock is the extra inventory kept on hand to prevent stockouts due to unforeseen demand spikes or supply chain disruptions. Effective safety stock management involves calculating the right amount of buffer stock needed for each warehouse, considering factors such as lead times, demand variability, and service level requirements. For a multi-warehouse operation, safety stock levels must be carefully calibrated to avoid excess holding costs while still ensuring product availability.

Effective Communication and Coordination Across Warehouses

Centralized Communication Channels

Clear and consistent communication is crucial for ensuring that all warehouses are aligned with the company’s overall goals and strategies. Centralized communication channels, such as a unified communication platform or an integrated WMS, allow teams to share information, coordinate tasks, and resolve issues quickly. For iStore iSend, maintaining effective communication across their warehouse network is essential for ensuring smooth operations and timely order fulfillment.

Regular Performance Monitoring

Regular monitoring of warehouse performance helps identify areas for improvement and ensures that all locations are operating at peak efficiency. Key performance indicators (KPIs) such as order accuracy, pick and pack times, and inventory turnover rates should be tracked and analyzed regularly. By continuously monitoring these metrics, businesses can identify trends, address bottlenecks, and make data-driven decisions to enhance their multi-warehouse management strategy.

Cost Management in Multi-Warehouse Operations

Location Optimization

Strategically locating warehouses closer to key markets can significantly reduce transportation costs and delivery times.To achieve this, optimizing warehouse locations based on customer demographics, shipping patterns, and supplier proximity is essential for minimizing logistics costs and improving service levels.

Shared Resources and Cross-Docking

Sharing resources such as labor, equipment, and transportation across multiple warehouses can lead to significant cost savings. Cross-docking, where goods are transferred directly from inbound to outbound shipments without being stored, is another effective strategy for reducing handling costs and improving efficiency. For multi-warehouse operations, these practices help maximize resource utilization and minimize waste.

Conclusion

Multi-warehouse management is a critical component of modern logistics and supply chain management. For businesses like iStore iSend, which provide fulfillment services across e-fulfillment, retail, and various types of businesses, mastering this aspect of operations is essential for achieving efficiency, reducing costs, and enhancing customer satisfaction. By leveraging advanced technologies, implementing best practices, and focusing on sustainability, companies can optimize their multi-warehouse management strategies and position themselves for long-term success in the competitive logistics landscape.

If you’re ready to take the next step and enhance your business operations, iStore iSend offers tailored fulfillment solutions to meet your needs. Click “Contact us today” below to explore how our expertise can drive your business forward